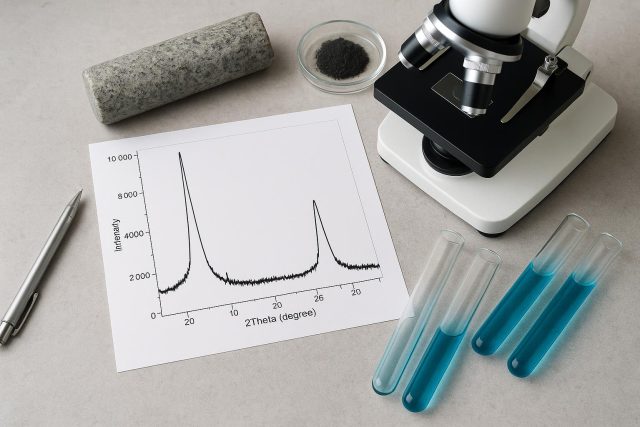

When researchers hit roadblocks in material science, pharmaceuticals, or engineering projects, they often turn to X-ray diffraction (XRD) for answers. This powerful analytical technique has become indispensable in R&D labs worldwide, solving complex problems that can make or break innovative projects.

Material Identification and Phase Analysis

Contents

One of the biggest headaches in research comes from not knowing exactly what you’re working with. XRD eliminates this guesswork by providing precise material identification.

- Unknown sample analysis: When you receive a mystery powder or crystalline material, XRD quickly identifies its composition and crystalline structure

- Contamination detection: Spotting unwanted phases or impurities that could compromise your research results

- Polymorphism studies: Identifying different crystal forms of the same compound, which is crucial in pharmaceutical development, where different forms can have vastly different properties

- Phase transformation monitoring: Tracking how materials change under different conditions, like temperature or pressure

Quality Control and Structural Characterization

Research teams often struggle with inconsistent results or unexpected material behavior. This is where analytical expertise becomes invaluable, and H&M Analytical XRD services can provide the detailed structural information needed to solve these challenges.

- Crystallite size determination: Understanding particle size distribution affects everything from drug dissolution rates to catalyst efficiency

- Strain analysis: Detecting internal stress in materials that could lead to failure or unexpected performance

- Texture analysis: Determining preferred crystal orientations that influence mechanical properties

- Quantitative phase analysis: Measuring exact percentages of different phases in mixed materials

Innovation Support and Problem-Solving

XRD doesn’t just identify problems, it guides solutions and drives innovation forward.

- Process optimization: Fine-tuning synthesis conditions to achieve desired crystal structures and properties

- Failure analysis: Understanding why materials didn’t perform as expected by examining their crystal structure

- New material development: Characterizing novel compounds and understanding structure-property relationships

- Stability testing: Monitoring how materials degrade or change over time under various environmental conditions

The beauty of XRD lies in its versatility. Whether developing next-generation batteries, formulating new pharmaceuticals, or creating advanced ceramics, this technique provides the structural insights needed to push boundaries.

Accelerating Research Timelines

Perhaps the most valuable problem XRD solves is time. Instead of spending months on trial-and-error approaches, researchers can quickly understand their materials at the atomic level. This knowledge allows them to make informed decisions about synthesis routes, processing conditions, and potential applications.

XRD analysis also helps validate theoretical predictions and computational models, bridging the gap between theory and real-world application. When research teams understand the “why” behind material behavior, they can more effectively design solutions and predict performance.

For research and development teams facing material characterization challenges, XRD offers a clear path forward. It transforms educated guesses into scientific certainty, helping researchers solve problems faster and more efficiently.