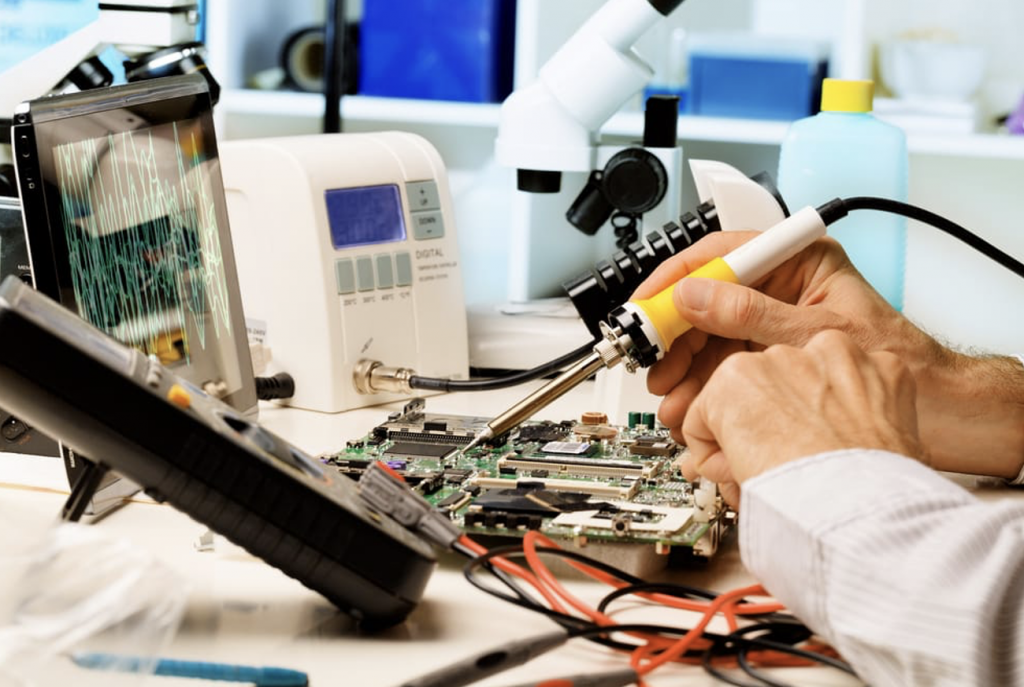

The utilization of Printed Circuit Boards has been universal across ventures. Like with different enterprises, PCBs are additionally observing broad application in the clinical business as increasingly more clinical exploration and treatment strategies become innovation-driven. With the lives of patients in question, it’s a given that these gadgets are strategic and that rigid rules should be adhered to with regards to Medical PCB Prototype. Obviously, there can’t be an occurrence where there is a breaking down instrument when a basic, lifesaving operation is being completed. Little amazement then that these instruments should be fabricated to a few exceptionally demanding principles.

There should be solid conventions connected with PCB plan, manufacture, PCB gathering, testing, and examination. Despite the fact that clinical gadgets are shifted, and their utilization is boundless across capacities and there should be explicit norms and guidelines connected with their utilization, here is a fast outline of the expansive Medical PCB Assembly Standards and Regulations:

There is one thing that is a flat-out must with regards to clinical gear: it needs to fill in true to form, and it needs to work accurately each and every time it is utilized. There is not a remotely good reason for a defibrillator that doesn’t do what it is generally anticipated to, and a specialist can’t stand to be stunned by breaking down instruments when playing out a fragile activity. Along these lines, clinical hardware is worked by probably the strictest and requesting guidelines in the assembling business.

These severe norms additionally apply to the printed circuit sheets that are at the core of these clinical gadgets. The norms control how the PCBs are fabricated, archived, followed, tried, and examined. The way to get your clinical hardware guaranteed by each of the necessary administrative guidelines to get your item to advertise is to utilize a PCB contract maker (CM) who comprehends and works with these principles. This is the way the clinical gear guidelines and guidelines influence PCB fabrication for clinical gadgets, and what you want to realize when working with your PCB CM.

Clinical industry guidelines outperform specifications in basic areas of different ventures like aviation and auto frameworks. Be that as it may, while considering the idea of the clinical business, this differentiation appears to be fitting, as clinical gadgets are planned and worked to protect, save or improve the nature of human existence. All things considered, they request the most significant level of investigation. A few associations add to the heap of clinical gadget guidelines and principles. For instance, the ISO is liable for two broadly executed worldwide norms—ISO 13485 and ISO 14971. These norms characterize the rules for quality and hazard the board, separately.

For clinical gadgets used in the US, the main principles and rules are characterized by the FDA under CFR 21-H Part 820. These guidelines cover everything from the structure of clinical gadgets to how to acquire endorsement for their utilization. As a considerable lot of the present clinical gadgets are made out of hardware, knowledge of these guidelines is required for anybody creating circuit sheets for clinical gadgets.

Clinical gadget gatherings might be presented to:

Fluids

Shock

Outrageous temperatures

Numerous gadgets live in or on the human body. Hence alone, any glitch can be incredibly hazardous and free you up to risk issues.

Here it pays to work with a PCB producer acquainted with a high-dependability gadgets plan (also known as Class 3, which we’ll examine beneath). Your hardware contract producer ought to be equipped for assisting you with planning to oblige risk concerns.

The other portion of an extraordinary well-being first demeanor centers around neatness.

Clinical gadgets should not be difficult to clean and sanitize. This might impact what sort of fenced-in area you use – – tempered steel is a characteristic answer for clinical requirements.

For instance, tempered steel is not difficult to clean, which is the reason it is utilized so frequently in clinical gadgets. A comparative however unique choice is conformal covering, which can ensure against:

1;Tainting

2;Dampness

3;Erosion

4;Dust

5;Salt splash

Then, at that point, there’s the disadvantage of cleaning. Some clinical cleaning utilizes ozone openness to kill microorganisms. Some hardware can corrupt ozone, so the part choice is vital here.

One last thought: Interaction with other clinical gadgets, including clamor emanation, can be a planning concern. You don’t need impedance with somebody’s pacemaker, for instance.

Planning and assembling a framework that collects a clinical gadget with different parts was the greatest test. The machine was expected to get parts collected from infeed transports. Thus, including the item’s bowl taken care of was not a need.

The gadget gathering had a few varieties and required a framework control that empowers the administrator to move from collecting different model options quickly. Additionally, it was essential for the framework to incorporate a generally existing machine for conclusive pressing. The framework was uncommonly intended to;

1;Consequently, feed parts on transport lines.

2;Handle distinctive gathering setups.

3;Completely track items utilizing the framework.

4;Yielding into a pressing machine.