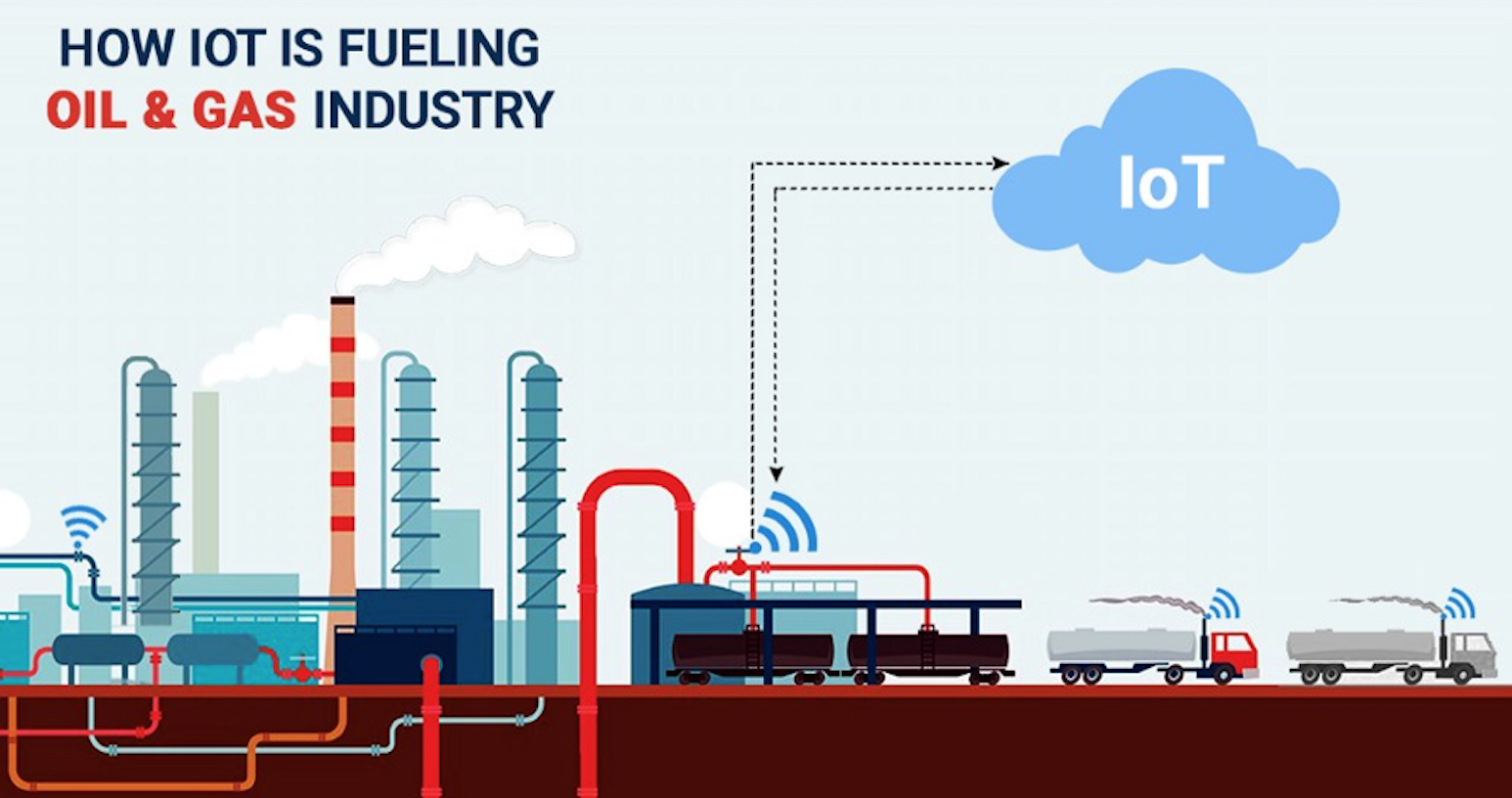

The Oil and Gas industry is harnessing the power of data and took a leap towards improving the efficiency and safety of the industry by gradually adopting Internet of things (IoT) in Oil and Gas industry. With increasing usage of devices, sensors, and well-connected pipelines have improved the efficiency, decision making, asset tracking, and real-time management of the industry. The Oil and Gas industry should determine their own strategy to optimize the use of the IoT as it caters the following real-world implications:

1. Remote monitoring and tracking:

The recent economic downturn brought the Oil and Gas industry into a critical need of adopting a high-level monitoring and tracking system. With Industrial IoT technology, one can form an internet of devices and can communicate the information between the devices. Monitoring of overall system performance is done once the information is collected from each system which tells when to schedule repairs and maintenance. When the system experiences a malfunction, high-pressure situation or any other dangerous issue it alerts the concerned authority immediately.

2. Reduced risk and Improve security:

With the current SCADA (Supervisory Control and Data Acquisition) system, that the Oil and Gas industry is been using for almost 20 years, the cybersecurity is the main concern as the SCADA systems are not capable of evading cybercrimes. Drilling, upstream operations and production have been at the highest cyber risk and an advanced risk management strategy like IoT in Oil and Gas is need to be adopted. IoT in Oil and Gas helps to reduce the risk in all three areas along with building a security wall that reduces the probability of cybercrimes.

3. Real-time tanker/fleet management:

Sensors, fitted inside the fleet, enables real-time tracking of location and health of vehicle in real-time. The intelligent fleet systems have helped the Oil and Gas industry to increase overall efficiency and reduce traffic accidents. The IoT sensors can communicate data to cloud from anywhere to monitor the data and equipment from multiple locations. Even if any hazardous operational incident occurs, a geolocation system, powered by IoT in Oil and Gas, can alert supervisors immediately.

4. Sustainable environment:

Sustainability is a broad term which includes safety in the environment and social issues. To have a sustainable environment one should not avoid environmental hazards like waste and spills which in turn harm our environment and cause various diseases. IoT has emerged as a superhero in Oil and Gas and takes cares of following economic factors that can assure a sustainable environment:

- Economic efficiency — Optimized use of economic resources.

- Climate strategy — Renewable items and low carbon fuels are used so that it does not cause any harm to the environment.

- Health and safety of workers

5. Equipment check and preventive maintenance:

The Oil and Gas industry requires a large amount of capital investment in equipment. And the industry faces losses when any equipment fails. One can get accurate and up to date analysis of the data which in turn tells about the failure of equipment well before. Alerts like low battery, coolant temperature, and engine alerts save the equipment from the failure before the time. All of this can be realized with the Predictive Maintenance feature of IoT. Notifications and alerts for low fluids and overheating engine help in improving the future usage of the equipment. The warning signs save the cost for Oil and Gas industry and improve the efficiency of the equipment.

Pipelines by far are the safest and most cost-effective way to move a large amount of Oil and petroleum and Natural Gas. As the sensors are being incorporated into the Oil and Gas industry, they monitor temperature, flow, pressure and many more. An end-to-end connected pipeline helps in inspection with the help of sensors. Neither monitoring hundreds and thousands of pipelines was an easy task nor the identification malfunctioning of those pipes. IoT in the Oil and Gas industry eradicated this challenge and made this as an easy task. The newly connected end-to-end pipeline helps to prevent the accidents and detects the leaks much faster by sending alerts and sending the notifications.

The Oil and Gas companies have started to adopt IoT and in near future, The IoT in Oil and Gas will replace the SCADA Systems and be an inseparable part of the Oil and Gas industry.

Author Bio

Sanjeev is the Chief Executive Officer (CEO) of Biz4Intellia, responsible for leading Biz4Intellia’s global business strategy and operations. Being an Internet of Things (IoT) enthusiastic from the beginning of its professional career, Sanjeev loves to read and write blog/articles related to the disruptive technologies that are trending.